Call Us:+86 17381572955

Who We Are

CozyActive is a professional manufacturer of yoga wear and activewear based in China, serving global brands with full-package OEM & ODM solutions. Founded by a team of textile engineers and fitness enthusiasts, we’ve spent over a decade perfecting the balance between performance, comfort, and style. Let you have a nice yoga practice day. Today, we are trusted by boutique fitness brands, e-commerce startups, and established wholesalers across the world.

At CozyActive, we believe that movement should feel empowering, inclusive, and aligned with every individual’s. Our modest activewear collection was created from the understanding that many women seek comfort, coverage, and confidence — not compromise. We design apparel that honors personal beliefs, cultural diversity, and emotional well-being, while still delivering high-performance support for yoga, fitness, and everyday life.

To us, modest activewear is more than a style preference. It represents a mindset: the freedom to move without hesitation, the confidence to show up as you are, and the comfort of knowing you belong. Through thoughtfully crafted silhouettes, breathable fabrics, and timeless designs, we aim to create pieces that protect your privacy, celebrate your strength, and inspire consistency in your wellness journey.

Our mission is simple yet powerful — to make movement accessible and enjoyable for every woman, whether she dresses modestly for faith, for comfort, or simply for herself. By blending modern performance technology with graceful, functional design, CozyActive empowers women worldwide to step into every workout — and every day — with courage, elegance, and ease.

We don’t just produce garments — we bring your vision to life with consistency and care.

Our Mission

To empower global activewear and yoga wear brands with flexible, ethical, and high-quality manufacturing solutions — supporting every stage of growth, from emerging labels to established brands.

We believe great products are built through collaboration, transparency, and long-term partnership, not just production.

What We Stand For

We are committed to belivering more than garments — we deliver confidence, consistency, and reliability throughout the entire production journey.

✔ Premium Quality, Built to Perform

We focus on performance-driven activewear, combining carefully selected fabrics, precise construction, and strict quality control to ensure every piece meets both functional and aesthetic standards — without compromising on lead time.

✔ Flexible MOQs for Growing Brands

We understand the challenges of building a brand from the ground up. That’s why we support small and flexible MOQs, allowing brands to test, refine, and scale with confidence.

✔ Full Transparency at Every Step

From fabric souring and sampling to production and inspection, we believe transparency builds trust. Our clients stay informed at every stage — no hidden processes, no surprises.

✔ Responsible & Sustainable Sourcing

We actively prioritize sustainable materials and responsible sourcing practices, helping brands align product developement with modern consumer values and long-term environmental responsibility.

Our Commitment to Our Partners

We don’t see ourselves as just a manufacturer — we act as a development partner.

By combining technical expertise, responsive communication, and a solutions-driven midest, we help brands turn ideas into scalable, market-ready products.

Why Choose CozyActive

| ✅ 10+ Years Experience | ✅ BSCI & ISO9001 Certified |

| ✅ Seamless & Cut-and-Sew | ✅ Flexible MOQ & OEM/ODM Support |

We build long-term partnerships with fitness brands, influencers, and activewear startups who value trust, flexibility, and product integrity.

Responsibility has become more and more important.

We also value and highlight through our code of conduct. We have audits like ISO9001, BSCI, SGS and SEDEX.

Read more about why choose a bsci-certified sportswear supplier for your activewear needs?

Full Production Workflow

Quick Links:

1. Fabric Selection

Premium Materials We Use

- Nylon + Spandex

- Polyester + Spandex

- Bamboo / Modal / Coolmax blends

Polyester vs. Nylon in Activewear: Which Should You Choose? This article will give you answer.

Fabric Performance Tests

- 4-way stretch & recovery

- Pilling resistance

- Moisture-wicking & breathability

- Shrinkage and colorfastness

All sourced from audited mills with batch-level QC. The following is the instrument we use to test the fabric:

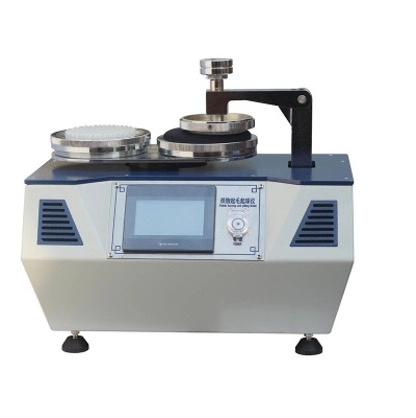

Professional fabric inspection machine

Hairball tester

Gram weight meter weighing instrument

Dry and wet rubbing color fastness tester

Professional four-way light box

Yarn density mirror

2. Sample Development

Pattern Development

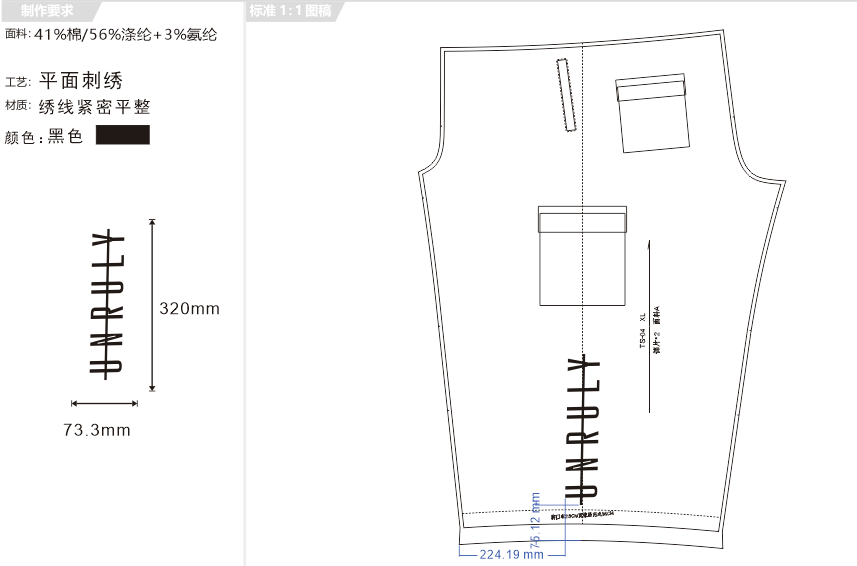

Cut & Sew: Tech pack → paper pattern

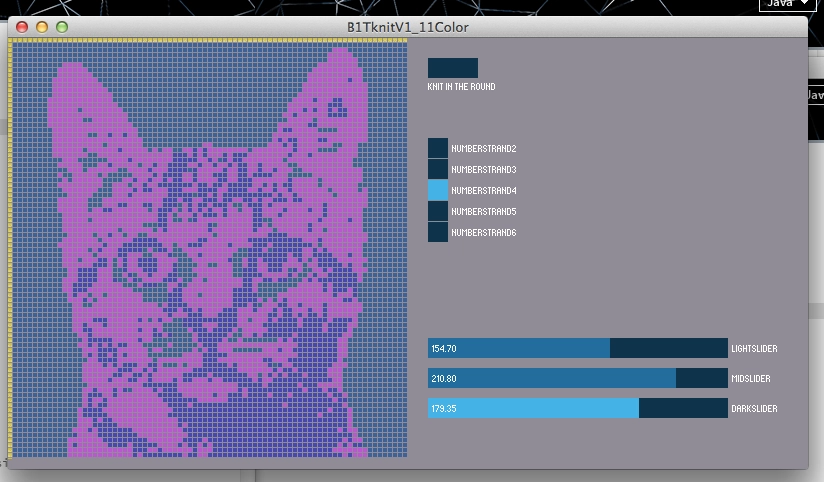

Seamless: Knitting program coding

Sample Cycle

- Production time: 7-10 working days

- Global shipping with tracking

Accurate fit, styling, and brand application confirmed before bulk.

3. Cut-and-Sew Process

- Fabric Cutting (Manual / Auto CAD)

- Logo Application (Print, Heat Transfer, Embroidery)

- Flatlock + Reinforced Stitching

- In-Line QC During Sewing

- Shaping & Steaming

- Final Inspection + Measurement Check

Each product goes through 2-3 internal QC checkpoints.

4. Seamless Production

- Circular knitting with Santoni / Lonati machines

- Yarn-dyed or post-dye with optional antibacterial treatment

- Assembly: waistband, gusset, logo, etc.

- Heat setting & shape retention process

- Elasticity & consistency inspection

No side seams, maximum comfort. The following is our factory to produce seamless series products:

5. Quality Control

4-Level QC Structure

- Raw Material Check

- Sewing Line QC

- Post-Sewing Inspection

- Pre-Packaging Final Audit

Full QC reports and video inspection available on request.

6. Branding & Packing

Custom Branding

- Heat-transfer logos, woven labels, print tags

- Hangtags, barcode stickers

Eco-Friendly Packing Options

- Biodegradable polybags

- Kraft paper wrap

- Custom printed boxes

Global shipping (EXW / FOB / CIF) with labeled cartons.

7. Why Brands Trust Us

What Sets Us Apart

- Seamless + Cut-and-Sew under one roof

- Certified production (BSCI & ISO9001)

- Flexible MOQs from 50pcs/style

- 10+ years export experience

- In-house design, sampling & R&D

“Reliable, professional, and fast delivery — CozyActive made our first launch incredibly smooth.” — Client from Europe

Ready to Manufacture Your Next Collection?

Whether you’re customizing your first leggings or scaling up a full collection, CozyActive is your trusted partner from concept to delivery. Our commitment to innovation ensures that our products stand out in the competitive market, just like lululemon.