Call Us:+86 17381572955

A Comprehensive Guide to Custom Yoga Wear

Today, yoga clothing has evolved far beyond just gym wear. It’s tight-fitting, quick-dry, and soft fabrics provide unparalleled comfort during exercise. This combination of functionality and comfort has made yoga wear increasingly popular for everyday attire. People now seek more personalized designs, moving beyond basic solid black options to vibrant colors and functional designs.

Yoga wear presents an excellent opportunity for small business startups looking to launch their own clothing line. The simplicity of yoga wear means there’s no need to worry about complex matching or intricate fabrics, as is often required in other fashion lines. Additionally, yoga wear is always in trend and sells well across all seasons, eliminating the risk of missing the optimal launch date. This makes it a low-risk, high-reward category for new entrepreneurs in the fashion industry.

How to Create Custom Yoga Wear for Your Business Brand?

Many people are eager to enter the custom yoga wear market but often hesitate, feeling overwhelmed and unsure where to begin. With Cozy Active, the process is straightforward and simple. Just follow these steps, and you’ll achieve your goals effortlessly.

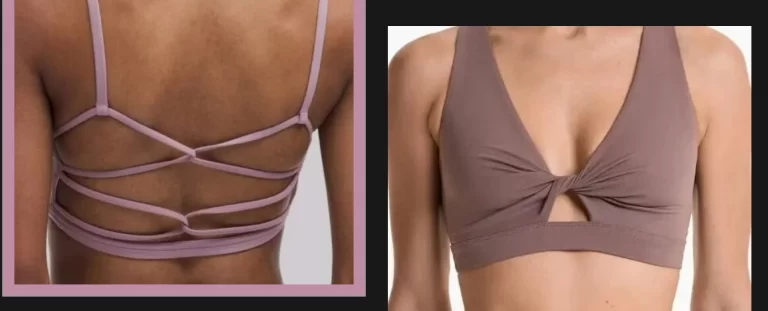

#1 Choose the Yoga Wear Styles

Designing yoga wear doesn’t require overthinking; the garments typically feature varying seam arrangements. You have the option to select from existing designs at the yoga factory or create your own unique designs and color schemes.

Full Range of Yoga Wear Options:

• Tops: Bra, tank top, singlet, t-shirt

• Bottoms: Leggings (full length, short, midi length, 3/4 length)

For design inspiration, you can:

1. Browse Google for ideas.

2. Create a sketch or illustration yourself or hire someone to do it.

3. Purchase a sample piece to use as a reference.

4. Choose from the factory catalog for ready-made designs.

With these options, you can easily customize yoga wear to fit your vision and brand.

#2 Choose the Fabric and Color for Yoga Wear

Yoga clothing is typically made from knit fabrics that offer strong stretch, skin-friendly properties, quick-drying capabilities, and a smooth, soft feel. Fabrics containing Lycra or spandex are especially popular in the market. Here are the four most commonly used fabrics for yoga clothing:

1. Polyester Spandex Blend: Known for its excellent stretch and durability.

2. Nylon Spandex Blend: Offers a silky feel and great resilience.

3. Cotton Spandex Blend: Combines breathability with stretch.

4. Recycled Polyester: An eco-friendly option with performance features.

These fabrics ensure comfort and flexibility, making them ideal for yoga wear.

#3 Select Yoga Wear Size and Quantity to Custom

Standard sizes like S, M, L, and XL are typically sufficient, but you can customize sizes and measurements to fit your market and end customers. Due to the tight-fitting nature of yoga wear and its strong stretch fabric, sizes generally run smaller than casual clothing but still provide an excellent fit.

The quantity you order will impact the factory’s cutting process. Minimum order quantities (MOQs) usually start from 300 pieces per style, though this can vary depending on the design and the factory.

#4 Create Prototypes and Samples

Before mass production, it’s essential to create prototypes and samples. This step allows you to evaluate the fit, comfort, and overall quality of your custom yoga wear. Work closely with your manufacturer to make any necessary adjustments and ensure the final product meets your standards. Prototyping is crucial for identifying potential issues and making improvements.

#5 Plan for Production

Once your prototypes are finalized, plan for production. Coordinate with your manufacturer to establish timelines, quantities, and quality control measures. Key considerations during this stage include:

• Lead Times: Understand the production lead times to ensure timely delivery.

• Minimum Order Quantities (MOQs): Be aware of the MOQs and plan your orders accordingly.

• Quality Control: Implement quality control processes to ensure consistency and high standards.

Effective production planning will help streamline the manufacturing process and prevent delays.

#6 Manage Logistics and Delivery

The final step in customizing yoga wear is managing logistics and delivery. Ensure that your products are shipped efficiently and arrive on time. Consider factors such as:

• Shipping Methods: Choose reliable and cost-effective shipping options.

• Customs and Duties: Be aware of any customs regulations and duties for international shipments.

• Inventory Management: Implement inventory management systems to keep track of stock levels and streamline distribution.

Proper logistics management ensures that your custom yoga wear reaches your customers without any issues.

How to Measure Yoga Tops Size(Garment Size)?

To accurately measure garment sizes, lay the item flat on a table. Here are the key measurements to take:

• Chest: Measure from seam to seam under the armholes.

• Shoulder Width: Measure from shoulder seam to shoulder seam.

• HPS (High Point Shoulder) Length: Measure from the high point of the shoulder to the bottom edge.

• Waist: Measure 17-20 cm down from the armhole seam to seam.

• Bottom Width: Measure the bottom edge from seam to seam.

• Neck Width: Measure from the inside seam to the inside seam.

• Front Neck Drop: Measure from the high point shoulder (HPS) to the front neck edge.

• Armhole: Measure from the sleeve head seam to the bottom sleeve seam, typically in a curve.

• Sleeve Length: Measure from the sleeve head to the cuff.

Yoga Wear Template & Design for Reference

A. Yoga Leggings with Pockets and Mesh Contrast

For many years, there has been a strong demand for sports wear with pockets. Pockets provide the convenience of carrying essential items like mobile phones, keys, or other necessities without the need for an additional bag.

Mesh contrast fabric has become increasingly popular in leggings due to its various benefits. It is sexy, breathable, and highly stretchable. Additionally, mesh is easy to match with different colors and is cost-effective, making it the number one choice for contrast fabric in leggings.

B. Tie-dye yoga pants

Tie-dye has gained significant popularity in recent years, characterized by a mix of light and dark colors. This technique can be applied to various fabrics, including cotton, rayon, bamboo, viscose, and modal, without strict limitations on fabric composition.

Rayon, bamboo, and modal are commonly used for tie-dye leggings, although these materials tend to be more expensive than plain-colored leggings.

C. Printed Fabric Tights

Custom print patterns on fabric can include flowers, animals, people, logos, or any design you desire.

Typically, the fabric is cut into four pieces: the waistband, right leg, left leg, and crotch.

D. Seamless Yoga Pants

This is an entirely different type of craftsmanship, where the fabric is knitted by a knitting machine, similar to how socks and stockings are made. This process usually requires a higher minimum order quantity (MOQ) of around 500 pieces per design, as the pattern is directly created on the machine.

Conclusion

Creating custom yoga wear for your business involves careful planning and execution at each stage, from understanding your brand and audience to managing production and logistics. By selecting the right fabrics, developing unique designs, and maintaining high standards of quality control, you can produce custom yoga wear that enhances your brand’s reputation and meets your customers’ needs. This approach not only differentiates your brand in a competitive market but also fosters customer loyalty and drives business growth.

If you want to custom your own yoga wear, please feel free to contact us at any time!